|

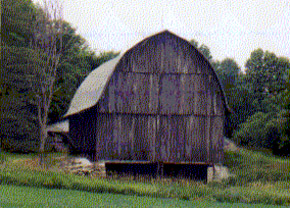

The Seager BarnOsceola County, Michigan |

![]()

Nicole Seager Freeman�s great-grandfather Earnest Alfred Seager built his barn in 1906 at a cost of $300! Augmenting the $300 was undoubtedly a lot of �sweat equity�. Earnest homesteaded about 1900 after spending time in the West gathering buffalo bones for fertilizer (a short-lived industry after the demise of the great herds) and working as a lumberjack in Michigan�s Upper Peninsula. The farm was very new when this barn was built from timber felled on the farm.

The

40� x 60� basement barn is about 40� to the peak.

Due to the flat Midwest topography basement barns often required an earthen

ramp or approach to reach the hay storage level; this barn, however, was able

to utilize a hillside and enter the upper level at almost grade.

The

40� x 60� basement barn is about 40� to the peak.

Due to the flat Midwest topography basement barns often required an earthen

ramp or approach to reach the hay storage level; this barn, however, was able

to utilize a hillside and enter the upper level at almost grade.

The Seager barn was once painted red but has long ago taken on a weathered patina. I suspect the siding is of Michigan white pine that once covered the northern part of the state. When Earnest arrived in 1900 the virgin white pine had been almost entirely cut in the previous thirty years, in part, to rebuild Chicago after The Great Fire. After the area was timbered, the homesteaders had to remove the stumps and debris. It was common for farmers to closely position the stumps on side and use them as fences.

The barn, typical of the period, is of post and beam construction with treenails holding beams up to 16� x 16� into mortises. The lumber was cut at the farm�s sawmill and the thrifty Earnest forged all the square cut nails as well as his tools, probably during those long Michigan winters. The use of square cut and particularly hand-made nails at this late date is unusual.

I

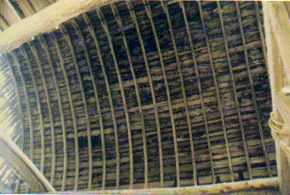

would describe the roof as a shallow gothic or almost round roof, which was

also popular in adjacent Mecosta, Clare and Isabella counties.

A round roof uses framing made of nailed up planking and cut to a radius,

or green lumber bent and pulled into shape.

Nicole reports that her great grandfather devised a system of 1� x 4�

sapling slats to form the roof radius.

I

would describe the roof as a shallow gothic or almost round roof, which was

also popular in adjacent Mecosta, Clare and Isabella counties.

A round roof uses framing made of nailed up planking and cut to a radius,

or green lumber bent and pulled into shape.

Nicole reports that her great grandfather devised a system of 1� x 4�

sapling slats to form the roof radius.

Earnest used large cut fieldstone for laying the walls for the basement. Here the dairy cattle, hogs and the beloved draft horses were stabled. Nicole�s grandfather Clayton was the last farmer in the neighborhood to make the change from draft horses to tractor.

It was Clayton who built the field stone silo in 1937. A stone silo is quite rare. Northern Michigan was covered in pre-historic times by a glacier that left a heavy deposit of stones; it was only natural that Clayton Seager used them for his silo. There are also quite a few homes in this area constructed of fieldstone. Farmers joke that stones are their best annual crop�each spring the heaving of the frost brings a new harvest!

The Seager homestead is north of the heavier corn and soybean ground of southern Michigan. Northern Michigan, like northern New England, became a tough place to make a living from the land with the low farm prices prevailing after the Korean War and today there are few families engaged full-time in agriculture. But, while the region lacks fertility and a longer growing season, it is an outdoors paradise with four seasons of sport activities, lack of urban congestion and a pristine environment.

Although

Nicole lives thousands of miles distant in CA she values the hard work and oral

reminiscences of her homesteading ancestors.

There is the story of grandfather Clayton and his cousin Arlo balancing

themselves on the open rafters of the partially completed barn in the summer

of 1906. Clayton�s mother, aghast

at the danger, wanted to yell from the kitchen door, but restrained herself

for fear of startling Clayton and causing an accident.

Of course, the reader already knows that Clayton survived to build the

silo.

Although

Nicole lives thousands of miles distant in CA she values the hard work and oral

reminiscences of her homesteading ancestors.

There is the story of grandfather Clayton and his cousin Arlo balancing

themselves on the open rafters of the partially completed barn in the summer

of 1906. Clayton�s mother, aghast

at the danger, wanted to yell from the kitchen door, but restrained herself

for fear of startling Clayton and causing an accident.

Of course, the reader already knows that Clayton survived to build the

silo.

Nicole remembers haying which was similar to this author�s own experience on another Michigan farm. The mow had a hay car that traveled on a track at the barn�s peak. Slings made of rope and boards were laid on the wagon rack and the loose hay loaded onto it from the window. After three feet of loose hay was on the sling, another sling and finally a third were laid in turn on the rising load.

At the barn each sling would be pulled to the peak of the barn with heavy manila ropes threaded through the hay car and down to a pulley on the floor (Earnest made his own 6� x 12� main pulley). The end of the rope was attached to a team of horses (later to a tractor) and the loaded sling pulled to the peak as the team walked across the yard.

Then you pulled the loaded sling that was locked and suspended from the hay car along the track to where you wanted to drop the hay. Finally, you gently swung the sling and if you did this carefully without prematurely tripping the load, you could deposit the load in the corner of the mow and avoid forking it into place by hand.

Advancing

age and economics of the small farm spelled the end of Clayton�s farming activity

in 1964 and he died in 1974. Although

Nicole spent only one year of her youth at the farm she remembers the snowy

winters, the livestock, and picking dinner from the garden.

Now she returns from CA each summer to revisit her roots and invariably

make another improvement. In recent

years the barn has been roofed and the house re-plumbed and painted. But someday, Nicole is determined to return to Michigan

and become the 4th generation Seager to make her home on the century

old farm.

Advancing

age and economics of the small farm spelled the end of Clayton�s farming activity

in 1964 and he died in 1974. Although

Nicole spent only one year of her youth at the farm she remembers the snowy

winters, the livestock, and picking dinner from the garden.

Now she returns from CA each summer to revisit her roots and invariably

make another improvement. In recent

years the barn has been roofed and the house re-plumbed and painted. But someday, Nicole is determined to return to Michigan

and become the 4th generation Seager to make her home on the century

old farm.

By Charles Leik, from notes by Nicole Seager Freeman

![]()